Lowest price poultry and livestock feed pellet machine feed pellet mill production linepoultry and livestock feed pellet machine feed pellet mill production line Introduction of poultry feed pellet mill 1).This series pellet mill can press all kinds of crops straws and sawdust into pellets,whoes diameter is from 2.5- 10 mm,the length can be adjustable. 2).Then the pellets can as feedstuffs ...

Grain pellet machine, also called Grain pellet mill, is a kind of equipment that can make grains such as soybean, wheat, and corn into feed pellets. Phone/Whatsapp : +86-15238391768 Email : sales@gcfertilizergranulator.com

Nov 21, 2018 · Both movements are opposite to each other. Hence, this design of cooler is called counter flow cooler. In addition to heat, moisture is also removed from pellet during the cooling process.

The feed pellet machine is a kind of equipment mainly used to make animal feed, generally using biomass such as soybeans, forage, straw, rice husk, and corn as raw materials. After the material is crushed and stirred, the pellet machine will extrude them into particles with uniform size and neat shape. The smooth-grained feed processed by this

Cattle Feed Pellet Machine is used to make small pellets for feeding chickens, goat, sheep, pig etc. Any mixture can be used to form pellets. Price Range. Pellet machine for animal feed, pEllet machine price in India, PELlet machine in Tamil Nadu, PELLET machine for FISH FEED, PELLET machine in Coimbatore, pEllet machine making, PELlet machine

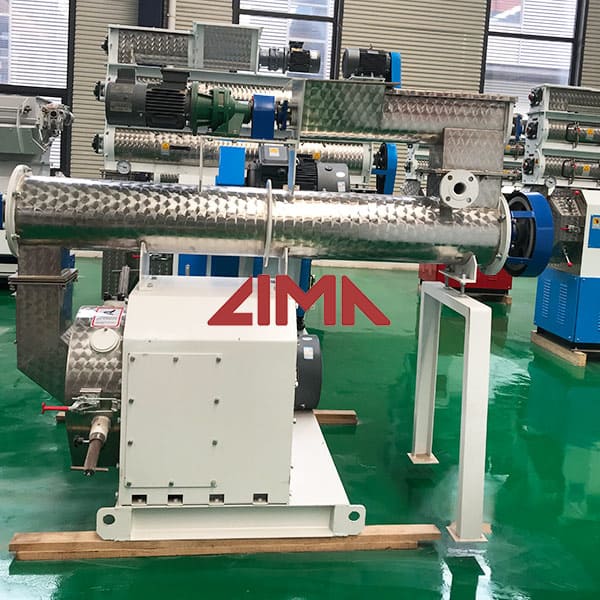

E-mail: enquiry@richimachinery.com. Whatsapp: +86 18574103366. High Efficiency. Hygiene And Safety. Fiexible Production. Customized Solution. SZLH-558 Cattle Pellet Machine. RICHI SZLH-558 Cattle Pellet Machine is based on crushed materials such as corn, soybean meal, and grass , alfalfa, It can be used for livestock and poultry feed

Galen et al. (2000) pointed out is a limitation to the use of the livestock feed that pelleting feeds produced many traits desired pelleting machine because of the high cost of by livestock producers which include decreased the equipment for pellet processing (FAO, 1997; feed wastage, reduced selective feeding, Kabuage et al., 2000; Eugene, 2002).

Made in India. The Export Model Pellets Making Machine (EMPMM) is one of the offered model of Pellets Making Machines manufactured by Rajkumar. As the name suggests, the EMPMM is a heavy duty machine fitted with a special gear box. It can be easily used for making Animal Feed Pellets as well as Biomass Pellets.

The animal feed pellet mill is mainly driven by the rotation of the die plate to drive the rotation of the built-in pressing roller to quickly squeeze corn, soybean meal, grass fodder, green fodder, etc. into pellets. Feed pellets processed by the commercial animal feed pellet machine can usually be used to feed cattle, sheep, chickens, pigs

Feed crushing machine Feed Mixing Machine Fish Feed Machine Fish Feed Production Line Poultry Feed Machine Flat Die Poultry Feed Pellet Making Machine Ring Die Poultry Feed Pellet Making Machine Poultry Feed Machine Line Chicken Feed Pellet Line 1-2t Chicken Pellet Line 100-1000kg

Feed Roller Mills for Cattle - Apollo MachineAll SvenMills comes with features built for feeding livestock in the most extreme environments. The SvenMill comes with a slotted fram Tel : + 8617337771729

800kg/Hour Cattle Feed Pellet Machine. Rs 2.5 Lakhs/ Unit. 500kg/Hour Cattle Feed Pellet Machine. Rs 2.5 Lakhs/ Unit. 150Kg/Hour Cattle Feed Pellet Machine. Rs 95,000/ Unit. 300kg/Hour Cattle Feed Pellet Machine. Rs 1.35 Lakhs/ Unit. 300kg/hr Goli Pend Machine.

The pellet feed made by livestock feed pellet milling machine requires a uniform size, with a diameter of about 3-20mm, a length of 1.5-2 times the diameter, a smooth surface, no cracks, and a compact structure. The pellet feed has different diameter requirements for different livestock.

Pellet Machine, Pelletizing Solutions Supplier & China Livestock Farm Use Pelletizing Machine Pellet Cooling Machine - China Pellet China Livestock Farm Use Pelletizing Machine

Different feed pellets require different compression ratio of ring die. So feed producers adopt corresponding ring die specification to ensure the feed pellet quality when making feed pellets for cattle in different stages. Cooling After leaving the pellet mill, the pellets have a temperature of 70-90℃ and the moisture of 15-17%.