The main process of floating fish feed contains: fish feed grinding→feed mixing→feed extrusion→pellet drying→oil spraying process→pellet cooling and packing. Generally mix raw materials together before grinding. The most common machine for grinding is the hammer mill. Floating pellets are loosely pressed when manufactured, so their

livestock hay pellet machine design sanjivani-Lima Fish Feed RICHI is a professional pellet machine manufacturer for feed pellet machines, wood pellet machines, straw pelletmachines, grass pellet machine, etc. Email Address enquiry@pellet-richi.com Phone/Whatsapp 0086-13838389622

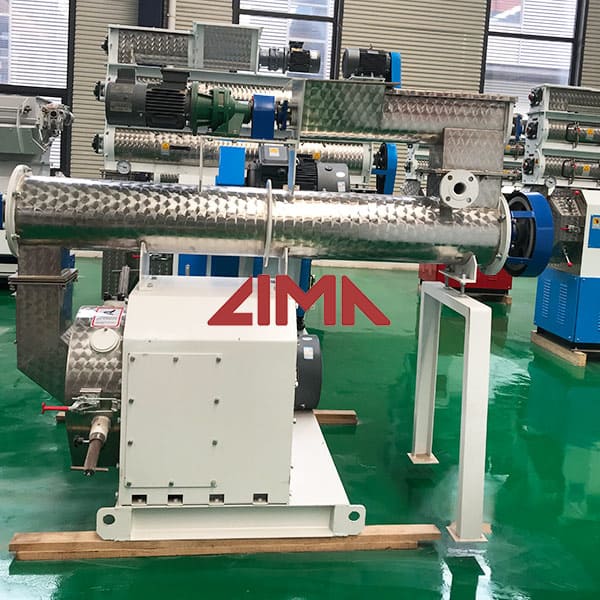

Bangladesh indonesia floating fish feed extruder pellet production making machine Brief introduction of floating fish feed pellet machine Main use: 1. Aquatic feed pellet for fish, catfish, tilapia, tilapia fish, shrimp, crab, etc. Both floating and sinking feed pellets. The floating time can be adjusted by the different puffing degree. 2.

Fish Feed/Pet Food/treats process line is use meat meal, fish meal, foodstuff,corn powder, soy powder, fishmeal to produce pets fodder.hot sales floating fish feed machinery in bangladesh requires the different outputs and Jinan ADO Food Machinery Co.,Ltd. believe that you can find what you need.1.

Pure Agro Food Farm is an Importer and supplier of Floating fish feed-making machines in Bangladesh. We are the authorized dealer of Strongwin machinery of C

Jan 31, 2022 · Normally corn- 40-50%, rice bran- 20-30%, soybean meal- 20-30%, fish meal- 5-15%, and other nutritional products are used in fish feed. Fish feed machine price in Bangladesh. Fish feed machine price depends on the production ability. Here is a shortlist of fish feed machine prices in Bangladesh.

16 YRS CN. Supplier. 4.9 (8) |. "Good service". Contact Supplier. The fish feed pellet size can be from 0.9-10mm to feed different sizes of fishes. The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours. Factory Price floating fish feed extruder machine floating fish feed extruder client visits. 1/6.

Fish Feed/Pet Food/treats process line is use meat meal, fish meal, foodstuff,corn powder, soy powder, fishmeal to produce pets fodder.manufacturer factory floating fish feed make machinery for bangladesh requires the different outputs and Jinan ADO Food Machinery Co.,Ltd. believe that you can find what you need.1.

After our survey of both offline and online vendors, we have come up with the price list below: Cecle Animal floating fish chicken poultry feed pellet mill making machine, grinder mixer machine: N163,000 – N819,000. WDL fish food processing floating fish feed mill pellet extruder machine: N90,000 – N300,000. Get Price.

Non-oil coated feeds account for 95% of total sales. Feed prices increased at a rate of between 9 and 15% per year from 2008 to 2012, due to increases in the price of major raw materials and unavailability. The retail price of 3–4 mm grower feed is currently 35–42 BDT/kg for sinking pellet feed, and 48–54 BDT/kg for extruded floating feed

15-25 working days for floating fish feed extruder machine: Packaging Details: Inside plastic film, outside wooden case for fish feed machine, or upon clients' demands. Fish Feed Machine Function: Floating/sinking fish feed production: Type: floating fish feed machine: Voltage: 110-480V: Power: 22KW: Warranty: 1 Year for floating fish feed

Floating Fish Feed Machine Extruder for Sale at floating fish feed pelletizer- - Lima Fish Feed MachineMar 18, 2022 · Making Floating Fish Feed in Kenya – Fish Feed Extruder By

Floating Fish Feed Milling Machine in Nigeria Farm – SupplyGoo Floating Fish Feed Milling Machine In Nigeria Farm Introduction The whole production line including Crusher-Mixer-Fish “Control the standard by the details, show the toughness by quality”.

The mixer can be used for grinding and mixing various livestock, poultry and animal feeds such as chickens, pigs, sheep, fish, rabbits, etc. It has the advantages of compact structure, low power consumption, small occupied area, convenient loading and unloading, less dust, safe and reliable work. The feed mill machine is divided into two parts