Since 1968, DAH TYAN HYDRAULIC Machine INDUSTRIAL CO., LTD. has been specializing in manufacturing hydraulic presses. For the past 43 years, we have produced more than 11,000 sets of Machines of their tonnage range from 20 to 10,000 tons mostly made-to-order products.

NDA ENGINEERING,394/3,nalla thanni thottam,Sanganoor Road,Ganaphthy,Coimbatore-06Veeramani v9976914686# Fish feed extruder machine# Automatic fish feeding ma

China Cold Feed Rubber Extruder, Rubber Extrusion Machine Cold Feed Rubber Extruder, Rubber Extrusion Machine picture from Zhejiang Baina Rubber and Plastic Equipment Co., Ltd. vi + 8617337771729

Rubber Extruder Manufacturers in India | Cold Feed Extruder Machines. Extruder. Extruders are heavy duty machines built to suit individual needs. We produce various types and sizes depending upon the production requirements for Straining, Extruding, Tubing, Slab production or Contour shapes.

Jun 01, 2019 · The throughput is the rate at which the feed sample fed into the machine is been recovered. This was obtained using Eq. (20). In this work, 3 kg of the homogenous feed mixture was fed into the machine and 2.2 kg of the feed was recovered at a time interval of 8 min.

Feb 24, 2016 · The length of a rubber extruder depends on whether it is a hot feed or cold feed extruder. Hot feed extruders are usually very short about 3D to 5D while cold feed ones range from 12D to 20 D . Screws are made of steel alloy forging, heat-treated to a machinable hardness and hard-chrome plated.

Product Information. INDEXPELL MAKE Cold Feed Rubber Extruder are suited for High Production, efficiency and eliminate porosity from Rubber Products. No warming mill required as cold rubber can be feeded at room temperature thus saving power and labour and cost of warming mills. INDEXPELL make cold Feed Extruders are designed Rubber Chords

Browse similar products RUBBER MACHINE; I. Name: Rubber Extruder, Cold Feed Rubber Extruder. II. Features: 1. Front Barrel: Outer barrel is made of high quality carbon steel; Inner bushing adopts 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment, surface hardness HRC65-70, hard layer depth 0.5-0.7mm; Bushing outer diameter of the ring is formed with an annular groove for

Rubber processing companies use cold feed rubber extruders because of their high production, continuous mixing, and precise extruding quality. Depending on the application, we offer cold feed rubber extruders with suitable die heads such as Straight Head, Cross-Head, Tread Head, Tube Head, and Strainer Head.

Cold-Feed Rubber Extruder - China Factory, Suppliers, Manufacturers. "Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Cold-Feed Rubber Extruder, Old Car Tyres Recycling , Tire Bead Cutter , Tire

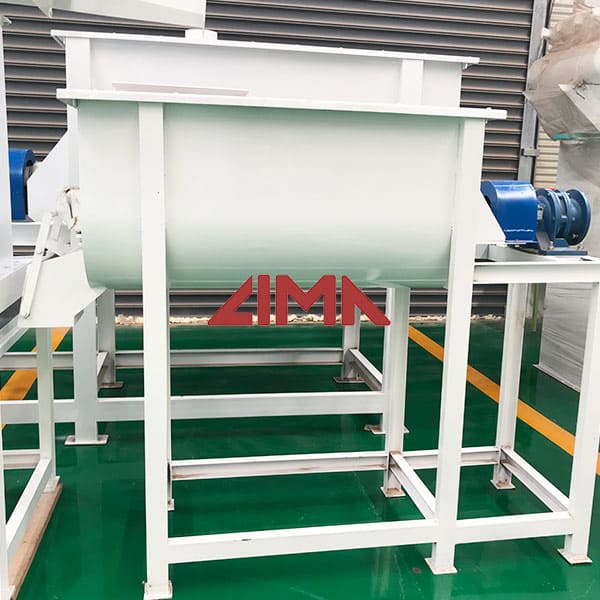

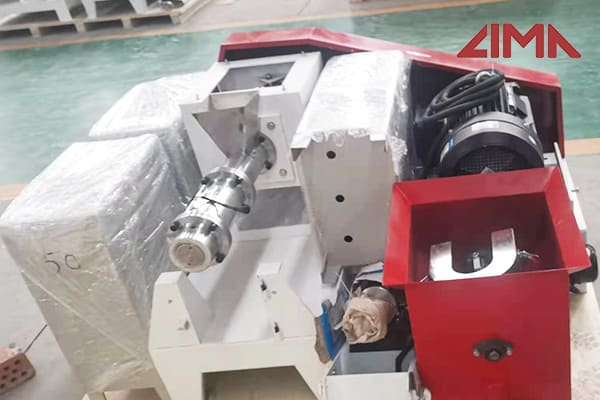

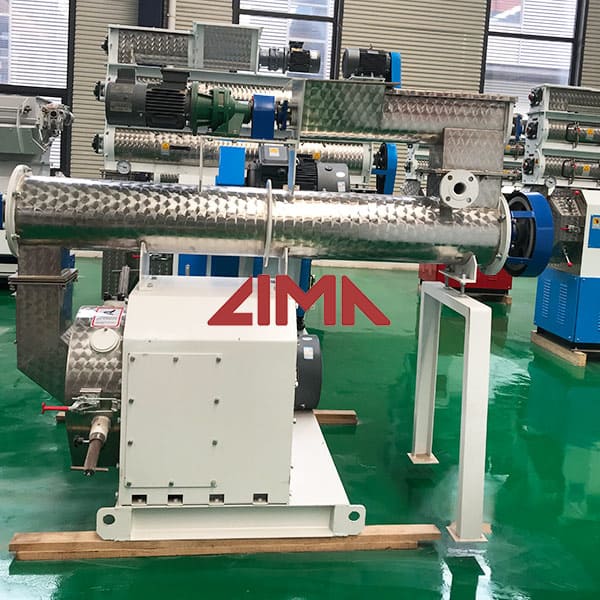

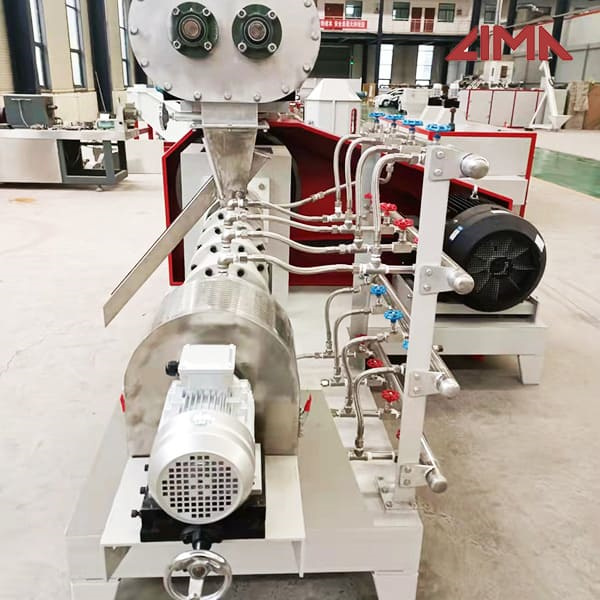

The production line mainly includes the following procedures: feeding→crushing→mixing→transferring→extrusion puffing→drying→cooling→spraying→pakacging. The raw materials is fully mixed and extruded in the twin-screw fish feed extruder, of which nutritional Get Price Extruder Gearbox in Coimbatore, Tamil Nadu | Get Latest Price

9000. Product description. 1. The screw is made from 38CrMoAIA materials with nitride depth 0.5-0.7mm and hardness HV950-1000. 2. The extruder’s feeding cylinder is composed of a rear body, front bushing and rear bushing. The structure is a jacketed cast iron style. 1. Rear body utilizes cast steel.

Buy Complete Animal Poultry Livestock Cattle Chicken Pig Complete Animal Poultry Livestock Cattle Chicken Pig Cow Fish Goat Feed Pellet Extruder Product Brochures , Fish Feed Extr Emai: sale@limamachinery.com

Mixing of 2/3 different layers of compound flowing on different screw flight paths, facilitates high shear uniform mixing that gives you consistency in the homogeneity of the mixed rubber compounds. ViamTek offers Cold Feed Rubber Extruder in Plain Barrel & in Vented as well with multiple sizes 45mm, 50mm, 55mm, 65mm, 70mm, 75mm, 90mm, 120mm

The capacity of twin-screw fish feed plant can reach 2 tons per hour. The production line mainly includes the following procedures: feeding→crushing→mixing→transferring→extrusion puffing→drying→cooling→spraying→pakacging. The raw materials is fully mixed and extruded in the twin-screw fish feed extruder, of which nutritional