Rubber Extruder Manufacturers in India | Cold Feed Extruder Machines. Extruder. Extruders are heavy duty machines built to suit individual needs. We produce various types and sizes depending upon the production requirements for Straining, Extruding, Tubing, Slab production or Contour shapes.

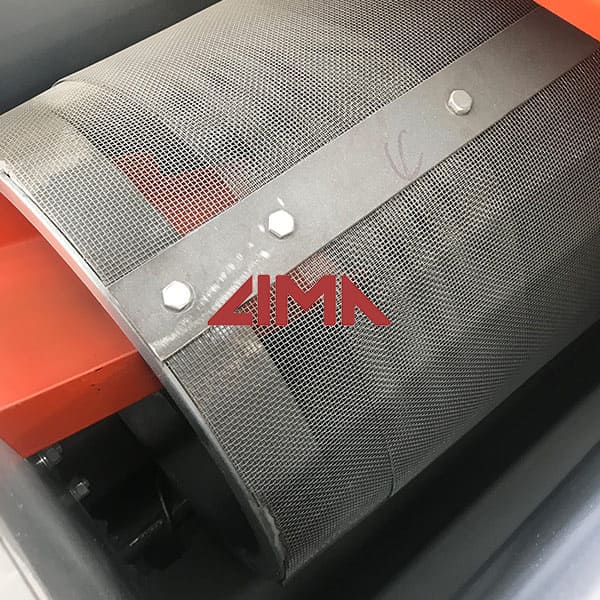

Product description. 1. The screw is made from 38CrMoAIA materials with nitride depth 0.5-0.7mm and hardness HV950-1000. 2. The extruder’s feeding cylinder is composed of a rear body, front bushing and rear bushing. The structure is a jacketed cast iron style. 1.

A special pressure melt transducer is provided which gives a pressure indication on the head & controls the screw rpm a per the set pressure valve enabling extrusion at a consistent pressure. Barrels are steel fabricated, jacketed for heating and cooling with replaceable liners. Feed rolls are specially designed for easy maintenance.

Cold rubber compounds are fed to the extruder by a slab feeder. The extruder heats and homogenizes the material and conveys the material into the Pork Chop head by means of a screw. The knives inserted into the Pork Chop head shear off material lumps , which are then further homogenized on a mill and fed into a hot feed extruder or calander.

The cold feed rubber extruder uses a gear surface with a hardened surface in order to reduce wear. This rubber extruder is also equipped with an automatic temperature control system, and the motor speed can be adjusted to any value to accommodate various production processes for different extruded products. We offer different types of cold feed

Mixing of 2/3 different layers of compound flowing on different screw flight paths, facilitates high shear uniform mixing that gives you consistency in the homogeneity of the mixed rubber compounds. ViamTek offers Cold Feed Rubber Extruder in Plain Barrel & in Vented as well with multiple sizes 45mm, 50mm, 55mm, 65mm, 70mm, 75mm, 90mm, 120mm

Browse similar products RUBBER MACHINE; I. Name: Rubber Extruder, Cold Feed Rubber Extruder. II. Features: 1. Front Barrel: Outer barrel is made of high quality carbon steel; Inner bushing adopts 38CrMoAlA high quality nitriding steel, quenched and nitrogen treatment, surface hardness HRC65-70, hard layer depth 0.5-0.7mm; Bushing outer diameter of the ring is formed with an annular groove for

Rubber Extruders. Our rubber extruders (feeders), can ingest full or partial bales of a wide range of rubbers including natural & EPDM. Rubber Bale Feeders are used for pelletizing or directly feeding a compounding extruder where the high viscosity rubber is a component in the formulation. In many plants a granulating system is currently used

Main features of the machine: 1.The machine screw and barrel optimized design to meet the majority of users of different formulations, different process requirements. 2. Automatic feeding section design novel and practical, feeding fast and convenient and safe.

These Cold Feed Rubber Extruders are ideally used for different types of rubber and sealants. We offer Cold Feed Rubber Extruders in plain barrels in ‘Vented’ & ‘Non-Vented’ designs in 55mm, 60mm, 75mm, 90mm, 120mm, 150mm scroll size for tubes, fire-houses, profiles, tyre treads, bead covering, blanks, slugs, apron-cots, fuel tubes

Selected Features: Type: Hot feed rubber, horizontal one-piece frame, extrusion die and rubber strip extrusion die. The machine can be heated and cooled automatically after the temperature control is set up. Temperature displays on the screen, and the control range is 40~100.

Acten Group started with a group of inspiring engineers, and has since expanded to become one of the key players in the industry. Before our start in 1994, there were very few business that were equipped to provide a total engineering solution in rubber and tire industry. Today, with more than 25 years of experience in the field, we like to

Mar 29, 2015 · Cold Feed Extruders are designed and manufactured with specially designed screws best suited for cold feeding of rubber. You can discuss with your manufacturer and avail various options of screws for a wide range of compound and extrusion applications. While manufacturers offer L/D ratio up to 24:1, the most preferred by end-users is generally

Rubber Extruding Machine Cold Feed---Awi

Since 1968, DAH TYAN HYDRAULIC Machine INDUSTRIAL CO., LTD. has been specializing in manufacturing hydraulic presses. For the past 43 years, we have produced more than 11,000 sets of Machines of their tonnage range from 20 to 10,000 tons mostly made-to-order products.