Our portable small pellets manufacturing plant can make pellets from a wide variety of raw materials, such as: wood, sawdust, rice husks, grass, of course including alfalfa. Its pellets output capacity is from 250kg to 350kg per hour. This homemade pellets production line contains crushing system, draught fan separation system, water tank

The pellet diameter can be made according to your animals,pellet range is 2 ~ 12 mm,the pellet length also can be adjusted ,pellet length is 1~5 cm. Technical Parameters Get Price NDA 500 Coimbatore pellet making machine 9976914686 - YouTube

Process Design Inc. - Offering Cow Dung Pellet Machine, Cow Dung Dewatering Machine, काऊ डंग डिवॉटरिंग सिस्टम, Sludge Dewatering System in Manjusar, Vadodara, Gujarat. Read about company. Get contact details and address| ID: 15962394297

Mini Cattle Feed Machine. Owing to our in-depth knowledge in this domain, we are specialized in providing Pellet Machine. We can make pellet machine from 4hp 1 phase to 100 hp 3 phase. Depending upon the requirement of our esteem clients. We aslo provide fully automatic pellet making plants at a very resonable price.

90-120KG/HR. MOTOR CAPACITY 5HP 3PHASE. Pelletizing machine is one of the biomass molding equipment.Working principle of Pelletizing machine. It can make powdered flour maize ,oil cake etc into pellets. The starting materials for the production of pellets are pressed by the pressing roller in the matrix.

Jul 26, 2021 · Alfalfa pellets, cubes, and hay provide the same essential nutrients per pound. Of course, almost all livestock and poultry animals are more suitable for lucerne pellets made by alfalfa pellet machine or alfalfa pellet processing line. But some farmers do use alfalfa cubes to feed horses.

The results show that animal feed pellet making machine is extensively applied to use of duck feed pellet making machine in animal husbandry, The animal feed pellet making machine is the ideal choice for making animal food like duck feed, chicken feed,fish feed and so on .this process is easy in operation and low in cost with a high survival

I. - Cattle Feed Machine is sold by Piece. - Most of the products of Cattle Feed Machine ranges from Rs 30000 to 1100000 per Piece. Cattle Feed Machine Price Range. No of Products (%) Rs 30000 - 74000. 17%. Rs 74000 - 180000.

CFPM. We provide Cattle Feed Pellet Machine with capacity 1 - 2 tonnes/ H. We are the leading manufacturers of Pellet machines in india & has lot of experience in Pelleting field. We can even customize the Pellet production as per customer requirement. This Pellet machine can also be used for Pelleting Sun Flower DOC, Soya DOC, Ground Nut DOC etc.

Amazing low cost animal food machinery At Fabulous Offers - Animal Machine Salt Lick Block Making Machine Animal Salt Mineral Block Licking Making Press Machine. $30,000.00 / Set.

I. - Cattle Feed Machine is sold by Piece. - Most of the products of Cattle Feed Machine ranges from Rs 30000 to 1100000 per Piece. Cattle Feed Machine Price Range. No of Products (%) Rs 30000 - 74000. 17%. Rs 74000 - 180000.

Vinglob Greentech Pvt Ltd. Contact Supplier. Super Quality Chicken Feed Making Machine, 60 To 90 Kg Per Hr. ₹ 62,000. Sigmatech Engineering. Contact Supplier. Potent Pellet Mill, 75 kg per hr. ₹ 68,000.

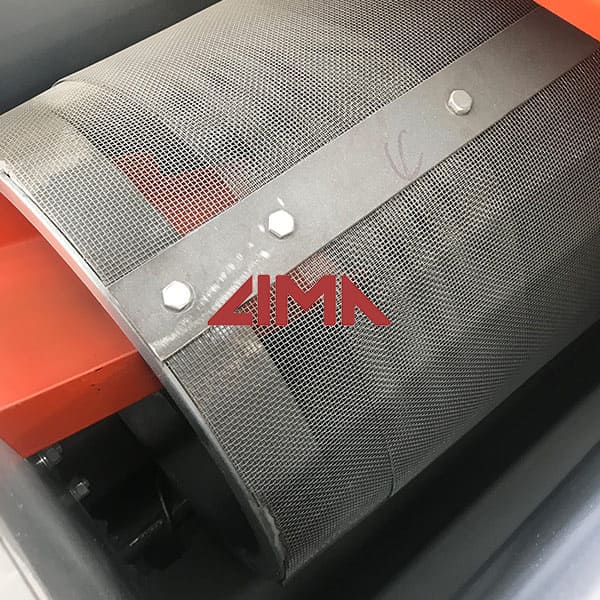

MZLH320 series ring die cow dung pellet machine ensures high capacity and efficient control of the pelleting process. The animal manure pellet mill is dimensioned for large and designed with exchangeable wear parts. Power: 37KW. Capacity: 600-800KG/H. Pellet Size: 6-12mm.

View Mobile Number. Call +91-8046054379. Contact Supplier Request a quote. Biomass Pellet Machine, 1000 - 1500 Kgs/hr ₹ 39 Lakh/ Set. Get Quote. Vertical Ring Die Pellet Machine, 600 - 1500 Kgs/hr ₹ 39.9 Lakh/ Set. Get Quote. Automatic Pellet Machine, Production Capacity: 1200kg/hr, 110 Hp ₹ 35 Lakh/ Unit.

When you grind it to small powders, the pelletizing rate and pellets quality will be better. Alfalfa after grinding. Final step. Then the most important step is coming. Put the alfalfa to the feeder of alfalfa pellet mill, they will be compressed to columned holes on the die and discharged from the machine. Thus the whole procedure is finished.