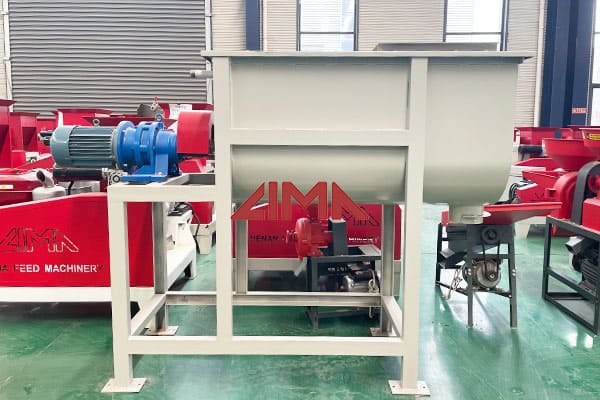

It has strong adaptability to the working site, solid structure, beautiful appearance and long service life. In order to improve the production efficiency, in addition to feed pellet machine, some auxiliary equipment for cattle feed pellet production are also needed to form complete cattle feed plant, including hammer mill, mixer, cooler, screw

Feed pellet cooler: 1.5: cooling down the feed to room temperature: +3-5℃ 5: Feed pellet sifter: 1.8: Grading screen is used to screen qualified pellet feed and separate impurities: 6: Feed crumbler: 4: For crush further feed pellet into 1-2 mm diameter for day-old chicks; for other animal, this machine can be removed: 7: Controlling cabinet

Mar 07, 2019 · The preferred choice for cooling is counterflow feed pellet cooler which has been the first choice in feed pelletizing plant. Pellet Cooling Machine Characteristics. 1. Cooling tank adopts octagon design, no dead angles. 2. Large inlet air area, outstanding cooling effect. 3. Discharging device adopts slide valve reciprocating type.

Cooling of the feed pellets is indispensable in the process of feed pelletizing. Feed pellets come out from the pellet mill are with a temperature of 70℃-90℃. The counterflow cooler can cool them.

In recent years we have supplied many projects & feed machines in Africa as mentioned: M/s Harsho Group Co Ltd. Box 810, Moshi, Tanzania, East Africa. Plant : 6-8 TPH mash feed plant. M/s Morning Fresh Farms. 2229,Zanaki Street, Avalon House. PO Box 20819, DSM Tanzania, East Africa. Plant : 2-3 TPH pellet feed plant.

I.T.I, Sasoli Road, Jagadhri Workshop. Yamuna Nagar, Haryana-135002. +91-9215459685 sales@larkenggco.com

RICHI can undertake 1-100t/h cattle feed pellet production line and provide more value-added service to all the customers (different output configuration can be customized). The main machines of cattle feed pellet production line is cattle feed pellet machine, feed hammer mill, feed mixer and others. *1-12mm pellet size can be choose , we also

Feed Pellet Machine Fish Fish Pellet Feed Animal Feed Pellet Machine For Making Pig Chicken Fish Feed Model ML-150 For Sale. US $591.00-$618.00/ Unit. 10 Units (Min Order) 2 YRS Hebei Qianhong Machinery Co., Ltd. 100.0%.

Practically 1 MT of material requires 5-6 square feet of area at 15 feet stacking height on maize density. For example: if we have to store raw material stock for 2 months and our daily production is around 100 MT we need ; 100 x 25 days x 2 = 5000 MT of storage for 5000 MT storage on maize density we need minimum space of 28,000 – 30,000

Oct 19, 2018 · The feed pellet cooler can cool down the hot feed pellets from 80 – 90℃ to about 3-5℃ above ambient temperature. The cool air flow could bring away the moisture around the wood pellets thus make the feed pellets dryer. The capacity of the counterflow pellet cooler varies from 3-20t/h, suitable for cooling feed pellets in large and medium scale animal feed pellet plants. It can also be used to cool wood pellets or other granular materials. Ingenious Devise of Feed Pellet Cooler

Large scale turnkey project 145,000t/a special aquatic feed 180,000 tons per year poultry feed pellet manufacturing factory in Jiangsu. Region: China. Product type: feed.

Livestock, cattle, sheep, cow, pig, camel, deer, rabbit, Alpaca, etc. is raised by people for meat, eggs, milk, leather, fur, and wool. Many of these livestock animals can be fed with feed pellets, as feed pellets have higher nutrition density, more comprehensive nutrition, higher economic benefits (animals can digest, absorb and conserve better) and are easier to store and transport than

Animal feed production machine can process various raw materials, can be used in feed production for rabbit, duck, cattle, chicken, sheep, pig and other animal. The whole production line consists of a hammer mill, mixer, pellet machine, cooler, crumbler and classifying screen. Easy to operate, each air inlet has a pulse type dust collector to

Pellet fed hogs not only gain faster but they do it with less feed for each pound of weight increase. Pelleting prevents the segregation of ingredients in a mixing, handling or feeding process. By feeding a pelleted feed, the animal is more apt to receive a totally mixed ration than one that has separated through these processes.

Animal Feed Mill Design & Layout. Whether planning to build a new feed processing facility or remodeling or upgrading an existing facility, many things must be considered, like: Plant layout design plays an important part in the design and engineering phases of any industrial facility. Ease of operation; avoiding disturbance in material flow i