Alfalfa pellet machine is a kind of pellet mill specially designed for making alfalfa pellets. Usually alfalfa pellets are used as cattle feed or fertilizer or fuel. But it has been widely recognized that they can also be used as fuel pellets for burning. When you are going to pelletize, the first step is drying alfalfa until the moisture is

Dec 24, 2020 · People prefer the briquette machine because of its mature technology, stable performance and sturdy build that last long. Briquette making machine price Facebook.com, @USAID Kenya. Ordinarily, a charcoal briquette machine cost between Ksh.75,000 and Ksh.125,000.

RICHI can provide the complete turnkey project biomass wood pellet production line, from design to install . Whether you want to produce wood pellet, sawdust pellet ,rice husk pellet, EFB pellet ,grass pellet or organic fertilizer pellet, the capacity is 1-100TPH can be choose. The main machine is wood chipper,wood crusher, drum dryer, wood

Apr 14, 2021 · 4. The possible effects of adding alfalfa to animal diets made by alfalfa pellet machine (1) Increase daily feed intake and speed up material circulation. The addition of alfalfa to the diet increases the cellulose content, which can stimulate the production of volatile fatty acids (VFA), resulting in a decrease in the pH value of the intestinal contents and a decrease in the number of E. coli.

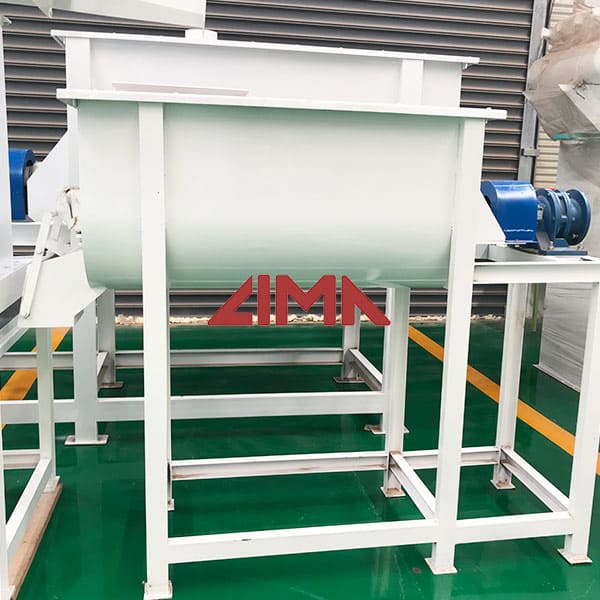

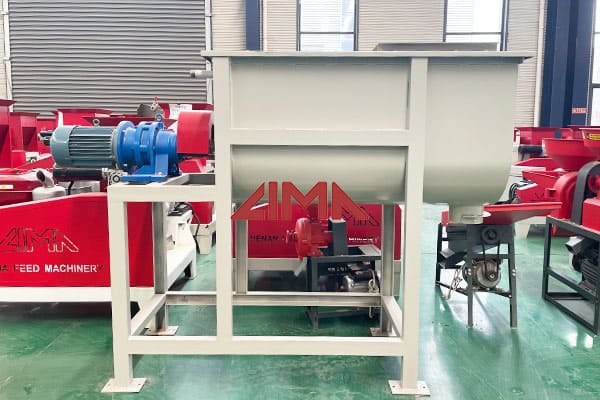

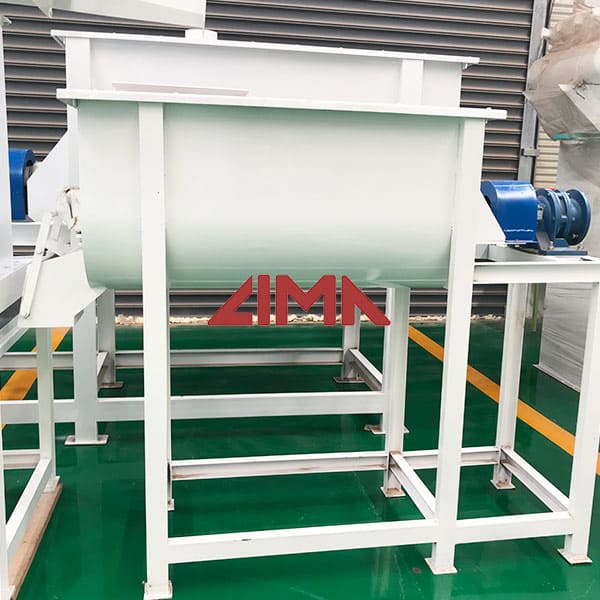

animal feed mixer in kenya manufacturers & suppliersChaff Cutter Machine , Rice Mill Machine , Grain Grinding Machine , Animal Feed Processing Machine , Silage/Hay Baler and Wrapp + 8617337771729

Oct 09, 2016 · Secondly, prepare a dryer. As we all know, the wetter or dryer material will affect the final quality of biomass pellets, so you need a dryer to get the suitable moisture, which is always about 15%. Thirdly, Grinding alfalfa to get appropriate size for the alfalfa pellet machine. Finally, put the alfalfa to the feeder of the alfalfapellet mill.

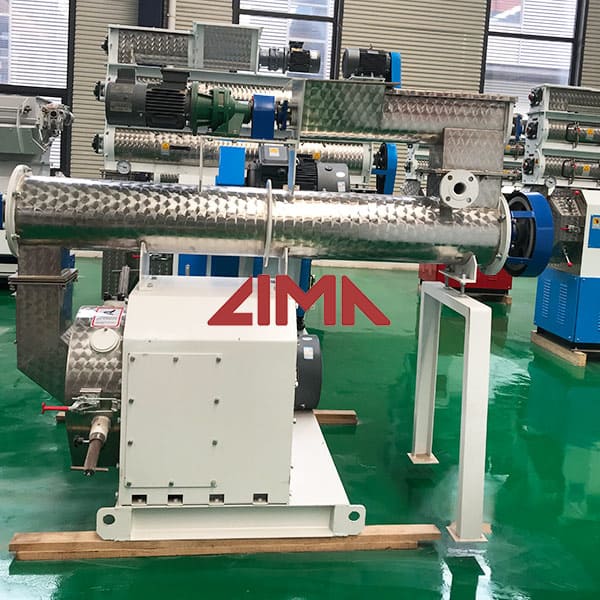

RICHI SZLH-558 Cattle Pellet Machine is based on crushed materials such as corn, soybean meal, and grass , alfalfa, It can be used for livestock and poultry feed, especially suitable for making ruminate feed,such as cattle feed, sheep feed, camel feed, the raw material can use grain and grass, if your raw material is alfalfa, this machine is the best choose.

Alfalfa Hay for Animal Feed and Pellet FOB Price: 150 ~ 500 / Metric Ton ( Negotiable ) Get Latest Price Min Order: 10 Metric Ton Supplying Ability: 84 Metric Ton / Month Payment Terms: Money Gram, Western Union, D/A, T/T Business Type: Trading No. of Employees: 16-25 Tags: Alfalfa Hay | Cattle | Feed

Aug 12, 2020 · Date: March 30th,2018. Installation cycle: 60 Days. Pellet Size: 1-6mm pellet. The main raw materials of customers are grass, alfalfa, corn and soybean meal. We have customized solutions for customers' raw materials. This alfalfa pellet production line is used for production chicken feed,cattle feed and sheep feed.

Sep 18, 2018 · The animal feed making machine is one of the most important part of 500 kg/h feed production line .It can process all kinds of grain feed into pellet feed,use to meet customer feeding chicken, duck, pig, cattle, rabbit, sheep, etc. The feed pellet making line production capacity around 0.5-1.5 ton per hour. YouTube. Jack Zheng.

Animal Feed Pellet Machines - Nukor Turn-key Small to The best option for Animal Feed Pellet Machines in Agriculture for Africa. Make Your Own Animal Feed from Turn-key Small to I

calf alfalfa pellet machine design in kenya wenzimiaoshu cow eating alfalfa pellet machine for sale sanjivani-Lima 9/10/2016 · Alfalfa pellet mill can help you make dehydrated alfalfa hay into pellets easily. Firstly, get your alfalfa pellet mill or pellet plant ready. If just for own use at home, a small pellet mill is enough.

Home » Blog » Fish Feed Machines » poultry feed hammer mill cost in kenya Small poultry feed mixer grinder unit 1tph for kenya Apr 25, 2018 · Screen size can be 1.5mm for pig feed production, 2,4,6,8,10,12mm for chicken feed production; The high size screen will have high yield.

Our portable small pellets manufacturing plant can make pellets from a wide variety of raw materials, such as: wood, sawdust, rice husks, grass, of course including alfalfa. Its pellets output capacity is from 250kg to 350kg per hour. This homemade pellets production line contains crushing system, draught fan separation system, water tank

When you grind it to small powders, the pelletizing rate and pellets quality will be better. Alfalfa after grinding. Final step. Then the most important step is coming. Put the alfalfa to the feeder of alfalfa pellet mill, they will be compressed to columned holes on the die and discharged from the machine. Thus the whole procedure is finished.