Yongfeng Machinery mainly provide poultry and livestock feed machine ,feed mixer ,feed crusher and screw conveyor. Yongfeng has more 10 years in feed pellet

Feed Mills in Bangladesh Full ListBRAC Feed Mills Ltd operates three feed mills, which are located in Manikganj, Nillphamari and Sreepur (Gazipur). BRAC Feed Mill in Gazipur produ + 8617337771729

The parts th at make up the livestock feed. pelleting machine are the frame, barrel, hopper, screw conveyor or auger, die, pulley and motor. The machined components were made of mild. steel

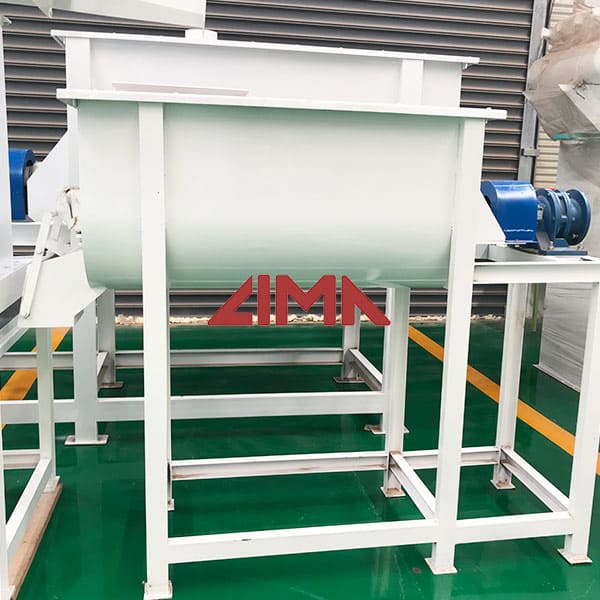

![<h3>20 t/h hour Poultry Feed Mill Plant [Turnkey Project Design]</h3>](/wp-content/themes/lima/load/50/feed mixer machine08.jpg)

Factory Capacity: Produce 20 tons feed pellets per hour (equal to 120,000 ton/year) Application: This feed milling project can process a wide range of livestock and poultry feed (chicken, duck, cattle, sheep, etc). Main Equipment: crushing machine, hammer mill, mixing machine, ring die pellet milling machine, cooling machine, packing machine

9/10/2016 · Alfalfa pellet mill can help you make dehydrated alfalfa hay into pellets easily. Firstly, get your alfalfa pellet mill or pellet plant ready. If just for own use at home, a small pellet mill is enough. For a pellet plant, you can take a large scale machine and related equipment. Secondly, prepare a dryer.

Makka Chunni Plant, For Cattle Feed Making, 1 Ton/Hr. Animal Feed Making Machine Sanjivani Agro Machinery. 250kg/Hour Poultry Feed Crusher, 300 kg per hr. Painted Full Automatic Makka Bharda Plant, Three Phase, 500kg/ Hr. Cattle Feed Plant, 200-250 kg per hr. Poultry Feed Grinder Machine, 1500 kg per hr.

Animal Feed Processing Machines. As with the automation trend in agriculture, more farmers are looking for labour saving, time saving and reliable machinery to increase their production quantity and quality. At Muharata we have developed our Animal Feed Processing Machinery along these same guidelines and offer a variety of machines ranging in

W.Q. Alali, S.C. Ricke, in Animal Feed Contamination, 2012. 3.2.2 Postharvest feed contamination. At the feed mill, animal feed can also become contaminated during feed manufacture or processing as a result of cross-contamination. The most critical point for microbial contamination at the mill is the post-processing heat treatment process.

Feed Cost As most beef steers require 12-14kgs of feed to produce 2kgs of live weight, ration cost are a major issue within a feedlot operation. The amount of feed required will depend on: • the weight and health of the starting calves • the quality of feed and a balanced ration • the genetics of the steers • the feed conversion ratio

Professional New Design Animal Feed Pellet Mill Cattle Pig Feed Pelletizer Machinery Livestock Food Processing Machinery , Find Complete Details about Professional New Design Animal Feed Pellet Mill Cattle Pig Feed Pelletizer Machinery Livestock Food Processing Machinery,Animal Feed Pellet Floating Fish Feed Pellet Machine Fish Feed Pellet Machine Pellet Machine Animal Feed Feed Pellet Machine

The STLP400 and STLP300 feed pellet plant remains a small poultry manufacturing machine operating at 600 to 1000 kilo gram per hour. You can also call it small animal feed pellet mill. This machine comes with great features of gringdine, mixing, pelletizing, conveying and cooling. The average diameter reading of the machine reads 2 to 8mm.

Feed Mills. Feed milling is the basic of Animal Feed Processing. From Poultry feed to Fish feed to Cattle feed. there is the necessity to grind the feed to allow mixing to occur. The Feed Mill is a vital part of Animal feeds processing. This type of mill is used for grinding various types of dried feeds such as grains, seed cakes, cereal husks

Production Output Range: 1~1000,000 tons/year. ABC Machinery supplied poultry and cattle feed plant adopts module design which can realize customized feed processing plant. Meanwhile, as an experienced feed mill machine factory, we can also help you make the best business plan for setting up your own animal feed pellet plant, like mini poultry

Sep 01, 2019 · Feed Pelleting Reference Guide Section 1: Introduction Chapter 3: Pellet Mill Design fluctuate due to the variation in feed ingredients and formulations, as well as to the pellet quality desired. The pellet mill manufacturer should be consulted as necessary for the ideal set-up regarding other